680 – IFAPME/FOREM TRAINING CENTRE

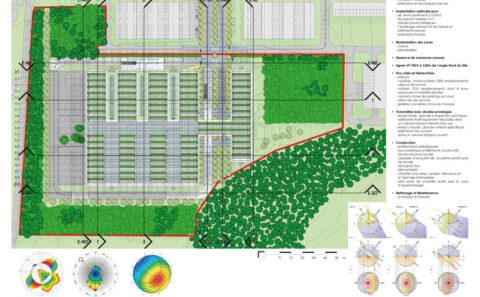

Chemin du Fontillois, 5001 Belgrade (Namur), Belgium 50°28’34 “N/4°49’17 “E 10,935 m²; 2022- ; (01/680).

Competition by invitation.

• Landscaping (with Syntax)

• Architecture (with Syntax)

• Structural engineering (with TPF Engineering).

• Building services engineering (with TPF Engineering).

• Environmental concepts (with Ecowal)

• Acoustics (with A-Tech)

• Accessibility (with Plain-Pied)

Introduction

The role of this college is to train craft workers across many sectors, including the construction industry. As a permanent partner to project developers and entrepreneurs, it must be exemplary at all levels.

– Firstly, its functional organisation has to encourage learning and mutual respect as well as questioning and communication.

– Secondly, its morphology must be brought back into line with good construction practice. This involves limiting the use of electromechanical resources to a strict minimum in order to minimise energy use (and therefore costs) while providing comfort for its users.

• On this topic, all stakeholders are now aware that the initial energy costs of construction (grey energy) and energy expended on maintaining the structure must be taken into consideration just as operating costs are.

• The morphology therefore needs both to favour natural lighting and ventilation, and to limit structural spans to the strict minimum.

• It must also accommodate all technologies, both in its design and in its operation, whether they are old or new, traditional or alternative.

• The very concept of a school built under a greenhouse can thus be part of the teaching: as soon as the necessary infrastructure work is completed, the building can be erected tidily, dry, with shelter from the wind, in reasonable temperatures, without cranes or waste.

• The impact of the construction on the biotope should be as limited as possible by reducing its footprint, so as to maximise the area for biodiversity. It is therefore proposed from the outset that the site should be planted densely with a mix of trees of native species, with a cutting plan that, over a period of 20 years, will ensure a balance of ages, as an extension of the existing protected natural area.

Site, construction and programme

– The site access road is oriented NE-SW. It provides access to:

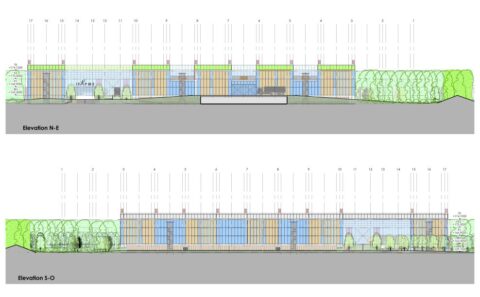

• to the south-west, a large industrial greenhouse under sheds, fully openable, 100 m long by 97 m wide and 10.8 m high. It envelops the “upper ground floor” (UGF) of the low buildings (LB) of two levels (E1 and E2), covering a “lower ground floor” (LGF) reserved for the covered parking (for 208 bicycles, 38 motorcycles and 206 cars, including 8 spaces for users with reduced mobility), technical premises and storerooms;

• to the north-east, another smaller greenhouse (78.3 m long, 16.2 m wide and 14.4 m high) housing a medium-sized building (MB) on 4 levels (LGF, UGF, E1 and E2), and the main pedestrian entrance.

– Taking the form of a village around a central street, the buildings are all (with the sole exception of the slab covering the car park) constructed entirely using prefabricated removable elements, using local resources and with minimal impact on the densely planted site. The whole complex is arranged on a 1.35 m square mesh. Particular attention has been paid to limiting floor spans to what is strictly necessary (maximum 6.75 m).

– The internal street is designed as the main space for socialisation. It is served by evenly distributed staircases and by two vertical circulation cores at its ends. All circulation within the complex is organised around it.

– A greenhouse connects buildings LB and MB on level UGF and serves as an entry point for goods traffic, which can also access the north-east façade of LB, as well as the outdoor learning area.

– The natural lighting and ventilation from the north-west facing sheds limits the area needed for solar protection of the vertical glazed surfaces and guarantees summer comfort.

– A simple and generic structure, naturally lit and ventilated, accessible throughout to people with reduced mobility, guarantees flexibility of use and facilitates subsequent reuse.

– The entire structure consists of prefabricated modules, both floor and wall elements. The latter are made up of modular panels 90 or 135 cm in width and 3.60 m in height which are strictly integrated into the 5.40 m structural modulation.

At the peak of the sheds, the solid modules of the facade can all accommodate gas or smoke evacuation ducts, as required now or in future.

The gables of the buildings facing the internal street are solid, without windows. The constituent panels are designed to support educational samples, materials and equipment. They also have a high sound absorption capacity.

– The footprint is kept down to 9,710 m² for the low-rise building (LB) and 1,225 m² for the medium-rise building (MB) (i.e. 10,935 m² in total). There is scope for an extension to the north and south-east of the site, allowing the floor area to be doubled.