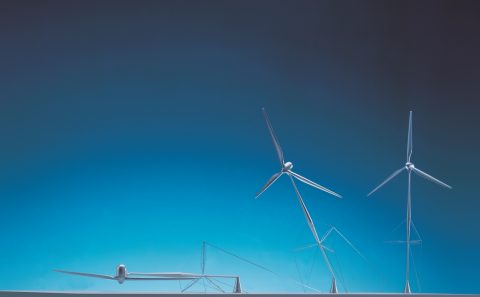

01/387-A Light Windmill Mast

Developed for Group Fabricom (International)

BELGIUM

(1999); (01/387) – (01/424).

- Structural Engineering.

- Structural design.

There is nowadays a certain contradiction between the aim of producing green energy with windmills, and the amount of material used for the construction of their masts and foundations, as well as the heavy equipment needed to hoist the turbines.

Masts and foundations consist typically of a large and heavy steel tubular structure, resting on a thick concrete slab sometimes supported by a large amount of piles.

The pollution of the ground by this important amount of poured in place concrete is a further burden from an ecological viewpoint. Finally, the massiveness of the shaft makes its imposing presence not suitable for every location.

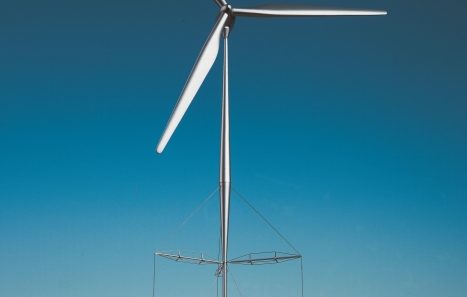

Samyn and partners has been appointed by Group Fabricom, a major Belgian group involved, among others, in the electromechanical industry, with a wide range of experience in the field of power transport and tower fabrication, to develop a lighter and more ecological windmill mast and associated foundations. Using the volume indicator method, developed by Dr Ir Ph. Samyn, it has been possible to show that a very light configuration, even lighter than a classical guyed mast, can be obtained by bracing the mast just below the propeller with three pairs of studded cables, arranged under a 120° star configuration. The cables link the mast to the studs at 45° and vertically to the ground. Alternatively and to increase the torsional stiffness, each pair of cables may link diametrically opposed points on the largest diameter of the mast to the stud heads, and continue in a vertical trestle configuration to the ground. In each configuration, three additional cables link diagonally, and in vertical planes, the connecting points of the studs with the mast to the ground.

This morphology allows furthermore to raise the mast vertically, after equipping it on the ground with the turbine and the propeller, using the mast’s own bracing cables as pulling device. It suppresses the need for heavy hoisting equipment, also allowing the windmills to be placed in remote locations.

With a quasi hinge connection at stud level, a 100 metre high steel mast can be composed of two opposed conical sections with a maximum diameter of 3 m and a minimal diameter of 1 m, on top of a cylindrical shaft of 1 m in diameter, resting on a conical base of 6 m in diameter housing the electrical equipment. The 1 m diameter minimal section cannot be reduced , as it is intended to house the cables coming from the generator and the ladder zone. The shaft may now rest on a limited number of prefabricated prestressed concrete piles and the cables anchored on concrete disks composed of radial segments, loaded by the soil. For a 100-metre high 1,5 MegaWatt windmill, the weight of the mast may be cut by half and its foundation system may easily be removed.

The stiffness, and thus the natural frequencies of these structures are comparable to those of a classical shaft.

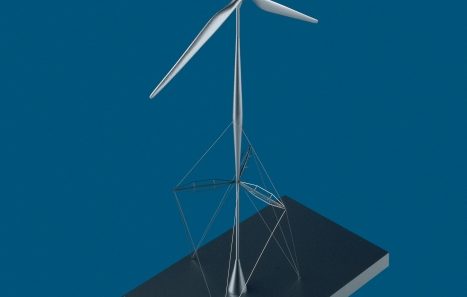

Alternative schemes have been developed as the other one shown here where the bracing cable returns to the mast base. In this case, there are hardly any savings on the foundations, but a weight-gain is still obtained for the mast. This alternative configuration may be suitable for offshore floating windmills.

The system may also be used to heighten the tower and substantially increase the turbine power of existing windmills, then reusing their mast in pure compression, relieving it from fatigue induced by bending stresses, as well as reusing their foundations.

This study is being carried out on behalf of the Fabricom group which submitted an international PCT patent application on 2004-04-16, but then withdrew it in front of the lack of interest from the market.

The Italian national society of electric energy, ENEL, in collaboration with Legambiente, organized in 2001 an international competition for two wind-farms in the south of Italy (Cinisi, Sicilia and Pescopagano, Basilicata).

Instead of 15 small turbines of 0.8 MW planned by the client, the project proposes 5 turbines of 2.5 MW on top of high masts.

The project of Samyn and Partners was selected among the projects exposed in Rome for the meeting “Paesaggi del vento” of 2002-06-27.

A prototype for a hub height of 62.5 m with a wind turbine JEUMONT J48 750 W has been preliminary certified by the Germanischer Lloyd WindEnergie GmbH for a IEC Type Classe IIA. Report n° 71480-5 / 2003.11.04.

| 01-387 | EOLE – A light windmill mast. |

| Client: | Fabricom Group |

| Architecture: | Partner in charge : B. Calcagno. Associate : T. Vilquin. |

• European Patent application, April 28th 2000; n° 00870090.8, Ph. Samyn: “Structure de support d’éolienne”, 23p; (Europe).

• Ph. SAMYN, Th. VILQUIN: “Structure de support d’Eolienne. Rapport de recherche. Notes de calcul».

Pour la Construction Soudée s.a. (group Fabricom). April 28th 2000. Internal report, 248 p; (01/387); (Belgium). This document is also available for consultation at the library of the Académie Royale des Sciences, des Arts et des Lettres de Belgique, rue Ducale, n°1 in Brussels.

• Request of certificate INTERNATIONAL PCT (Patent Cooperation Treaty) laid down Thursday April 26th 2001, under n° PCT/BE/01/00075. Ph. SAMYN : “Structure de support, en particulier, pour une éolienne “18 pages + 10 pages de figures. International publication 2001.11.08 sous le n° WO 01/83984 A1 [(2+10+6 ) pages = 18 pages ];(Europe).

• Demande de brevet INTERNATIONAL PCT (Patent Cooperation Treaty) déposé le jeudi 26 avril 2001, sous le n° PCT/BE/01/00075. Ph. SAMYN : “Structure de support, en particulier, pour une éolienne “18 pages + 10 pages de figures. Publication internationale 2001.11.08 sous le n° WO 01/83984 A1 [(2+10+6) pages = 18 pages]. Notification de délivrance. Demande n°01.927505.6-2315 ref. DPNE 132.989 LB. 2004.04.16 [(5+27)=32 pages] ; (EU). (E14_589).

• AERODYN Energie systeme Gmbh, Proviänthausstrasse 9, 24768 Rendsburg, Deutschland, “La Construction Soudée”, Preliminary Design of a Wired Tower for the wind energy conver ter Jeumont J48, 62,5m HH, TC2” ; Document – Number B-41.1.0-RT.00.00.01-B, Révision B ; 2001.04.18-, 31p; (Germany).

• DETAIL IN ARCHITECTUUR, July-August 2001, p 6 “Lichte windmolen” ; (Netherlands).

• Cobouw – dagblad voor de bouw, Tuesday October 23rd 2001, 145e jaargang, number 196, p 1 ; Ad TISSINK : “Getuide windmolen moeiteloos omhoog” ; (Netherlands).

• PROCEEDINGS of the FIFTH INTERNATIONAL CONFERENCE ON SPACE STRUCTURES, Guildford, England, 19-21 août 2002, (ISBN : 0-7277-3173-4),pp 1265-1274; Ph. Samyn, Th. Vilquin : «Light Windmill Mast with Cocked Guys»; (GB). (E14_644).

• ESPACE-VIE. Aménagement du territoire, Urbanisme et environnement, n°123, décembre 2001, couverture et pp 3-5 ; Anne NORMAN : “Les éoliennes, une énergie dans le vent ? ” ; (Belgium).

• INDUSTRIE MAGAZINE, 1 mai 2002; pp 54-55 : “Pour une architecture durable” – 1 mei 2002; pp 60-61 :“Duurzame architectuur”; (Belgium).

• BOUWEN met STAAL, n° 165, februari 2002, pp. 6-7; “Getuide windmolens”; (Netherlands).

• PAESAGGI DEL VENTO. A cura di Edoardo Zanchini. Meltemi editore, 2002, p. 106; “Leggero come il vento” (Italy).

• Edoardo Zanchini, “Paesaggi del vento”, Meltemi editore, Roma, 2002; (Italy).

• THE ARCHITECTURAL REVIEW, November 2003, n° 1281, pp 32-33, “Wind powermast prototype”; (Italy).

• Germanischer Lloyd – WindEnergie GmbH “Certification report” Wind Turbine : Jeumont J48 / Guyed Tubular Steel Tower : La Construction soudée / Hub Height 62,5 m IEC Type Class IIA – Report No : 71480-5 – Date : 2004.02.24; 5p; (DE). (E14_742).

• LES CAHIERS DE L’URBANISME n° 52, décembre 2004, pp. 30-32 ; “Mât d’éolienne léger” ; (BE). (E14_776).

• STAAL-ACIER, n° 6, mars 2005, pp. 22-25, “Lichetere windmasten – Des mâts d’éoliennes plus légers” ; (BE). (E14_783).

• Aldo AYMONINO, Valerio Paolo MOSCO :“Espaces publics contemporains – Architecture « volume zéro »”

Skira editore. Janvier 2006. (ISBN : 88.7624.274.0); pp.126-127 : « Service Station – Houten » ; pp. 352-353 : “A light windmill Mast”; (IT). (E14_837).

• Vraag & Aanbod (Kluwer), n°8, jaargang 59, dinsdag 2012-02-21 ; p14 ; Luc DE SMET : « Wind turbines kunnen een kwart goedkoper » ; (BE). (E14_1108).

Andres Fernandez.

For plans sections and elevations, please refer to the archives section of the site available from the “references” menu.