Page 68 - ELEMENTS EUROPA (EN)

P. 68

64

THE DARK SIDE OF THE LANTERN

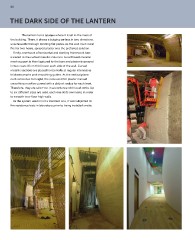

The lantern turns opaque where it is set in the mass of

the building. There, it shows a bulging surface in two directions,

unachievable through bending flat plates. As the wall must resist

fire for two hours, sprayed plaster was the preferred solution.

Firstly, a network of horizontal and slanting framework bars

is nailed to the curbed metallic columns. A cardboard metallic

mesh support is then ligatured to the bars and plaster is sprayed

in two coats (6 cm thick) over each side of the wall. Curved

metallic sections are placed horizontally at regular intervals as

thickness marks and smoothing guides. As the vertical plane

curb varies due to height, the rules used for plaster manual

smoothing must be curved with a distinct radius for each level.

Therefore, they are tailor-cut in accordance with local curbs. Up

to six different sizes are used, each one at its own level, in order

to smooth two-floor high walls.

As the system used is not a standard one, it was subjected to

fire resistance tests in laboratory prior to being installed onsite.