Page 219 - THE FIRE STATION

P. 219

217

to respond flexibly to needs, while being independently controlled – Systematic recovery of heat from extracted air during the heating

with a view to optimising occupants’ thermal comfort and limit- period;

ing energy consumption. Ventilation in each zone is subject to a – Limitation of distribution losses through rationalising and well-

programmed schedule. insulating all piping;

– Use of solar panels covering 20% of annual heating needs for

Air renewal rates are in line with the IDA 3 requirements set down producing hot water for WCs and showers;

by the norm NBN EN 13779 4 recommended by the Building En- – Use of a gas-fired CHP unit to cover hot water needs in winter

ergy Performance (BEP) decree 5 of the Walloon Region. months as well as an absorption machine to produce cooling for

16 hours a day in July and August.

HEATING The level of thermal insulation of the walls 6 together with the per-

manent occupation of most rooms limits the power reserve of the

The building’s heating system compensates for the thermal losses heat generators necessary to keep the building heated.

through both the building’s envelope and its ventilation and filter

systems as well as providing hot water for WCs and showers. Hot water for heating is produced in the basement central heating

These needs have been kept to a minimum during the design and unit mainly via two 320kW gas-fired condensing boilers combined

execution phase: with a 30kWth gas-fired CHP unit.

– Optimisation of the thermal performance of the building’s enve-

lope (cf. Chapter 6); Hot water for WCs and showers is produced on demand by a row

– Limitation of uncontrolled seepages of air into the “office” of four plate heat exchangers connected up to two 2,000 litre water

energy zone through the careful work of the company in charge storage tanks. Production is supported by 45m² of solar panels on

of structural work on the joints between the various construction the roof of the gym and connected up to the storage tanks.

elements;

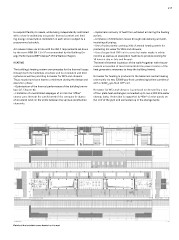

Details of the technical rooms located on the roof.