Page 220 - ELEMENTS EUROPA (EN)

P. 220

216

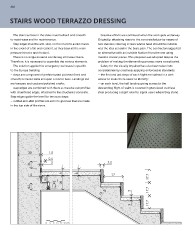

STAIRS WOOD TERRAZZO DRESSING

The stairs surface in the stairs must be hard and smooth Creative efforts are continued when the work gets underway.

to resist wear and for maintenance. Originally, attaching risers to the concrete below by means of

two stainless steel lag screws whose head should be invisible

Step edges must be anti-skid, not too hard to avoid cracks was the idea set out in the basic plan. The contractor suggested

in the event of a fall and resilient, as they bear all the main an alternative with an invisible fixation from the rear using

pressure (shocks and friction). metallic corner pieces. This proposal was adopted despite the

problem of making the dismantling process more complicated.

There is no single material combining all these criteria.

Therefore, it is necessary to assemble the various elements. Safety for the visually impaired has also been taken into

consideration by creatively applying enforceable standards:

The solution applied for emergency staircases is specific – the first and last steps of each flight are stained in a dark

to the Europa building. colour to make them easier to identify;

– steps are composed of prefabricated polished (hard and – on each level, the half landing giving access to the

smooth) terrazzo slabs set upon a mortar base. Landings too descending flight of stairs is covered in granulated stainless

are terrazzo and cast and polished onsite; steel producing a slight relief to signal users where they stand.

– step edges are combined with risers as massive oak profiles

with chamfered edges, attached to the structure’s concrete.

Step edges guide the level for terrazzo steps;

– rubber anti-skid profiles are set into grooves that are made

in the top side of the risers.