SEO Version

62

fg 8

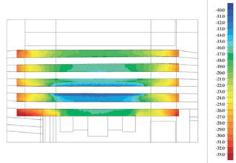

fg 7.1 The sound level under a fat cover.

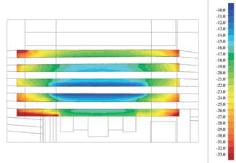

fg 7.2 The sound level under a simple arch.

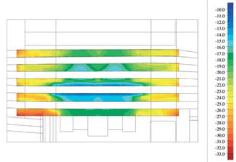

fg 7.3 The sound level of the competition design, identical

to fg 4.2, see there also.

noise within the separate modules, and suppresses the sound dispersion over the

whole area. The noise in the separate modules is largely absorbed because of the

perforated roof structure.

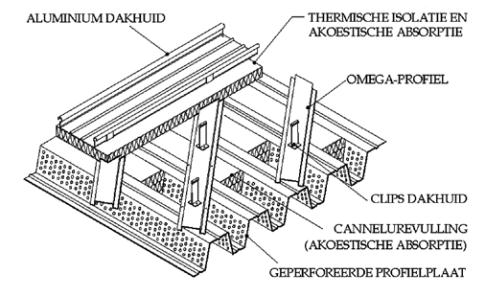

The perforated sheeting of the covering is an important element with regard to

noise control. In an ideal case it is 100% absorbent, promoting the same favourable

conditions of open air sound dispersion, without projection of sound into the direct

surroundings. This optimum value can only be approximated since a given surface

is never a full 100% absorbent. The proposed solution, using perforated sheeting, is

a compromise between sound absorption properties and ease of construction and

maintenance. The noise absorption is realised combining profiled roof sheeting with

perforated sides (perforation level of 30%), with a soundproofing filling covering

both the grooves and, in a reduced density, the entire area. This soundproofing filling

serves as a thermal insulation against cold surface condensation on the underside

of the aluminium weather sealing as well. Figure 8 shows a schematic presentation

of the structure of this roof.

To demonstrate the effectiveness of the soundproofing, calculations of sound

dispersion were made for a cover without soundproofing, as well as for a cover with

the proposed soundproofing.

Figures 9.1 - 9.2 indicate the distribution of the sound pressure levels on the platforms,

measuring the effect of soundproofing on noise dispersion.

Two situations are presented: a cover with soundproofed roof, and one without.

Both calculations were based on a sound source on track 3, length 100 m, Lw = 0 dB/m

(fig. 3)

.

Figure10showsasummaryof bothsoundcardcalculationresults inagraph indicating

the cumulative dispersion of the sound levels on the platforms. It is obvious that a

soundproofed roof has a positive effect on noise levels under the cover. The average

decrease in sound levels is 3‑4 dB(A). The total area of the more quiet zones during

aluminum roof

omega profle

thermal insulation and

acoustic absorption

roof clips

groove flling

(acoustic absorption)

perforated plate profle

Powered by FlippingBook Publisher